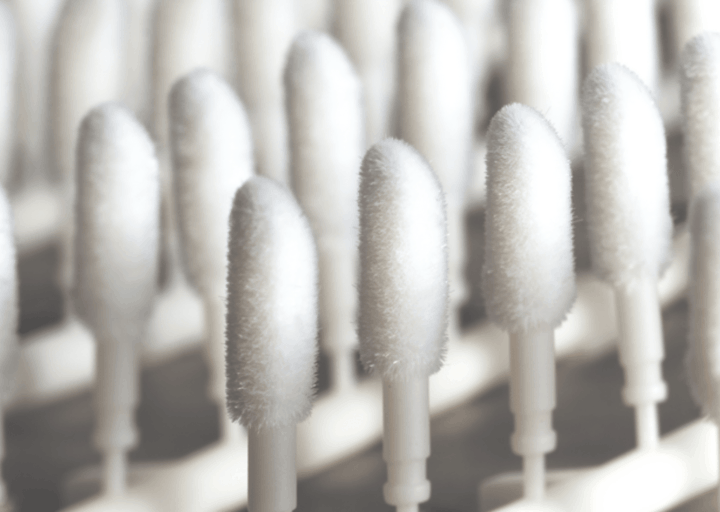

Tactility Speaks Flocking

Surface textures can be modelled with a variety of haptic perceptions as soft, rough, sticky, fibrous, waxy and so on. Soft and fluffy surfaces tend to be the ones that give us a sensation of comfort, cocooning and affection. With this in mind, this Material Monday, we explore flocking as a finish with velvet soft haptic experience.

Flocking is a highly distinctive and established finishing technique that not only creates optically beautiful and haptic objects but also improves the tangible properties of a product. Flocking can seal, adjust tolerances, reduce vibration noises, protect from high temperatures and reduce condensation.

The fibres used for flocking are mainly polyester, polyamide, viscose and cotton. Each can add additional properties to the substrate such as UV resistance, softness, sound- and water-absorption. This, and aforementioned vast range of improvements, can be achieved on almost all surfaces such as textiles, wood, glass, metal, plastics, paper and rubber.

Essentially, this process utilises short fibres. The short cut fibres are charged in an electrical field and vertically shot into the carrier material, which has been previously coated with an adhesive. Depending on the application, there are solvent and water based adhesives as well as one and two component adhesives available.

Described surface can be further customised with a range of finishing processes such as: printing, air embossing or foil embossing. It is noteworthy that the length of the fibres also determines the feel of the flocked surface (the smaller the length, the softer the result). However, length will also impact on the processability of loose flock (the smaller it is, the more difficult it is to process).

As mentioned above, depending on the fibres used, as well as their length and thickness, a wide range of sensorial reactions can be achieved. These range from velvety smooth to abrasive stiff. To exemplify, when using a precision-cut fiber we can create a smooth and even look, whereas fibers cut to a random length will result in a more patchy/cloudy look. All flock fibres can be dyed with any colour shade. Special colour shades are also possible by mixing different coloured fibres (mélange).

Flocking can be applied on a flat surface as well as to a three-dimensional object. It can serve both a purely decorative and functional purpose. Brands as Miele, Melissa Shoes, Porzellan Glas, Mercedez Benz or Rolls Royce feature amongst many others who explored how aforementioned tactile sensation can be used to an advantage of the product.

To conclude, flocking can be used to highlight key details and to create objects with a soft and friendly feel. It can also offer opportunity to use is as a function indicator – hold, press etc. This finish has the potential to create luxurious surfaces that are pleasant to touch and reassuring to hold. Aside from the spectacular haptic experience, consumers can also enjoy its optical qualities as polished matte, semi opaque and super opaque effects.

If you are interested to explore soft tactility of materials at our Material Library, or are interested in booking one of our CMF workshops titled ‘Tactility Speaks’, please feel free to get in touch.

Posted 01 March, 2018 by Katie Kubrak