Foil: Fact and Fiction, In Partnership with Kurz

Foil has long been a weapon in the armoury of creatives looking to elevate products, print and packaging to new heights. From shimmering metallics to classy, understated mattes, foil’s variations in colour, texture and finish bring an added dimension to projects that are designed to stand out from the crowd.

But unlike traditional methods of graphics application, – such as screen-printing, digital printing or lithography – comparatively little is known about how foil actually gets from A to B. What goes on behind-the-scenes to turn a blank sheet of paper into a shelf-ready carton, complete with crisp, eye-catching foil branding?

Likewise, as conversations around environmental responsibility have become commonplace, we are increasingly asked about the material composition of foil. Does it contain plastic? And can it be recycled?

We hope that this article, written in partnership with foil manufacturer KURZ, will lift the lid on some of these questions. We’ll separate fact from fiction when it comes to foil, and provide a better understanding of which foiling process is right for your next branding or design project.

Part 1: What is Foil?

Let’s start with the basics: Is what we call ‘foil’ actually foil?

Not exactly. Instead, ‘foil’ is convenient shorthand for what is, in reality, a plastic-free transfer product.

Transfer products are created by printing thin layers onto the back of a 12-micron film, made from polyethylene terephthalate (PET).

These printed layers are then transferred from the PET film and onto the final product in one of three different ways: hot stamping, cold transfer, or digital transfer.

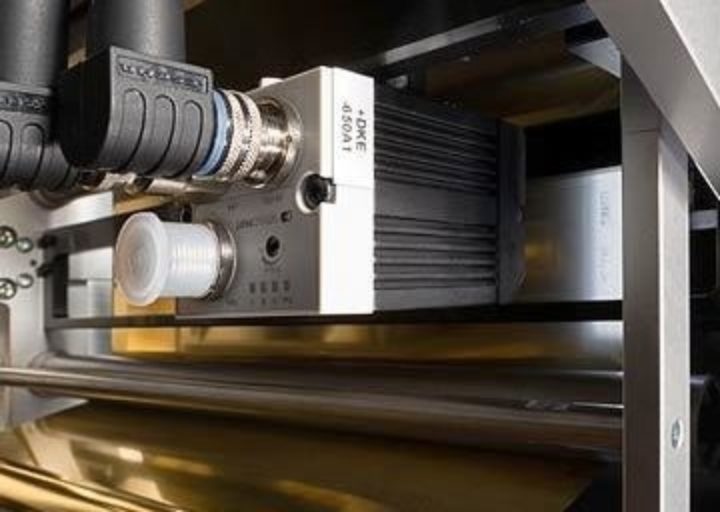

Hot stamping uses a combination of heat and pressure from a stamping die to transfer the printed layers onto a substrate material. These substrates may include coated and uncoated papers and boards, self-adhesive label stocks, flocks, leather, and even wood.

A combination of pressure and the engraving of the die allows for beautifully embossed and debossed surfaces. Particularly intricate dies can create stunning micro-embossed structures, which add another element of intrigue to a design.

Cold transfer, on the other hand, does not require heat or pressure to create the transfer.

Instead, using an offset – or in the case of labels, a flexo-printing process – an adhesive is applied to the substrate, before it is then brought into contact with the transfer product. The adhesive bonds with the printed layers, gently releasing them from the PET film and onto the substrate.

The cold transfer process is suited to smooth and coated substrate materials only.

If used on an uncoated material, the adhesive may soak into the stock and create a patchy finish. And because no pressure is used during cold transfer, any embossing or debossing must be applied as a separate process.

However, cold transfers do have certain advantages. Cold transfers can be run in line on a printing press, for example. And because no pressure is required, cold transfers can be overprinted to create layered, multicoloured metallic designs.

Digital transfer is comparatively new to the market. This process requires no dies or plates; as a result, it’s possible to create short-run and one-off designs, using real metallic transfer, without the setup times of conventional transfer methods.

The digital process allows for personalisation, coding, and the production of limited-edition pieces. And, like cold transfer, the absence of pressure means digital transfers can be layered and overprinted.

Part 2: How Sustainable is Foil?

Hopefully, by now, you have a better understanding of which transfer process is right for your branding or design project.

But what about foil’s sustainability credentials?

Having worked with all three foiling methods over a number of years, and analysed them from different angles, we’ve concluded that foil is a viable, sustainable option for surface decoration.

There is always variation within industries, of course. However, German manufacturer KURZ are an excellent example of best practice when it comes to environmental responsibility.

1. Manufacturing Process: KURZ is one of the oldest foil manufacturers in the world, and this experience has helped them to achieve efficiency rates of up to 95% in their production facilities. Aside from strict, mandatory German environmental standards, which go beyond local regulations in many locations, the company also works towards water, energy, air and waste savings.

2. Raw Materials: All raw ingredients are responsibly sourced.

3. Water: No water is used in the manufacture or transfer of foil products – which means, each time we choose foil instead of inks, we are essentially saving water.

4. Energy: KURZ were one of the first companies to re-use residual energy from the manufacturing process; production waste is thermally recaptured and reused to heat KURZ’s factory. In addition, the company’s German manufacturing sites use green electricity from wind and photovoltaic solar panels. Construction is currently underway on a power plant that aims to supply up to 25% of the energy needed at the group’s biggest manufacturing facility. It is estimated that the new plant will achieve a carbon reduction of between 7000 – 9000 tonnes of CO2 per year, which is equivalent to the production of between 3.5 – 4.5 million white cotton t-shirts.

5. Carbon Emissions: KURZ’s CO2 emissions are additionally offset via reforestation projects and investments into local projects that focus on green energy.

6. Release of Chemicals: No harmful chemicals are released into the environment, since KURZ’s exhaust air evacuation system emits 100% fresh air back into the atmosphere.

7. Recyclability: KURZ’s transfer products are plastic-free, have been independently tested and certified as fully recyclable and compostable. KURZ’s hot and cold transfer products were awarded 100/100 by INGEDE for their deinkable properties, even with 100% coverage. KURZ has also just introduced a closed loop system in which PET film (the carrier of transfer product) can be returned and recycled. Whilst it’s in its infancy, this scheme is planned to be rolled out on a larger scale in the near future.

8. Legislation: Wherever you go in the world there are different approaches to recycling, different legislation and different levels of infrastructure in relation to foils. This knowledge can be transferred, not only to satisfy ESG and CSR performance measures, but also as a direct benefit when writing a successful sustainable story.

9. Sustainable Story: What truly sets KURZ apart is the company’s approach to production waste. The PET film left over from production remains in the industrial waste stream, so it can be separately sorted and handled responsibly. And because it remains a valid raw material, it can be thermally recovered or recycled and processed further. Engineers at KURZ have now come up with a closed loop system to collect the PET material from their customers and introduce it into the recycling stream.

10. Functionality: Foil is ideally positioned to replace other graphic application methods, such as printing.

11. Applications: KURZ foils are suitable for all applications, including packaging, all printed materials, POS, marketing collateral, retail, products and more.

This article is the first of two features brought to you in partnership with KURZ, demystifying questions around foil and its sustainable credentials.

If you like what you see and require further information on anything featured in this article, please contact info@nirvanacph.com. We’ll be more than happy to help you tell your brand’s sustainable story.

Posted 08 April, 2021 by Katie Kubrak