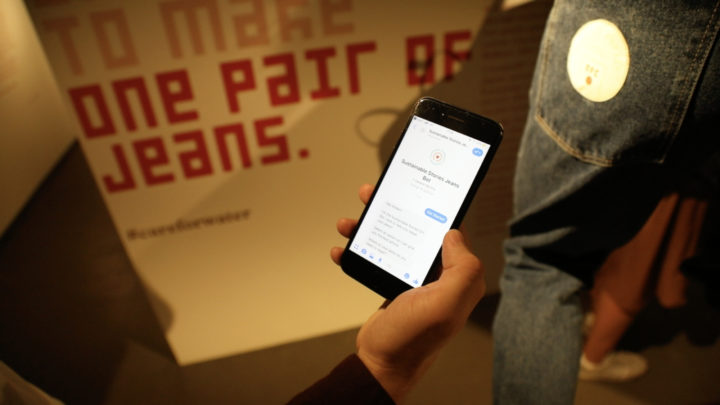

Sustainable Stories: How much water does it take to produce one pair of cotton jeans?

One of the most precious resources we have on the planet is water. The ocean is the most powerful force on the planet, feeding us and everything around us. Yet, the most important feature about it tends to be lost – 70% of oxygen we breath comes from oceans, not trees.

While oceans are composed of saline water, we need non-saline resources for both drinking and production. Out of all water on the planet only 2.5 % is non-saline. Out of this, only 0.7% is accessible to be used for aforementioned purposes.

With population and production raising exponentially and The United Nations anticipating that more than 5 billion people could suffer water shortages by 2050, sustainability is a topic that binds the global community, encompassing sustainable living, production and use of resources such as water and energy.

As desalination is a solution that can only further damage oceanic habitats (read more here), arranging the appropriately managed resources for your production is incredibly important. With the fashion industry being under the global microscope across material origin, production transparency, dyeing pollution etc. communicating authentic ‘sustainable stories’ is vital.

It all starts with textiles such as cotton as it takes 18 years’ worth of water supply for one person (approximately 2,900 gallons) to make one pair of jeans. With this in mind, cotton is an extremely thirsty crop. It’s also the world’s most popular natural fibre with production increasing dramatically over the recent years and growers turning to pesticides to satisfy demand. Therefore, the first step for brands is the need to embrace organic farming as an environmentally ‘healthy’ alternative.

As non-saline water will become scarcer over the next thirty years, the next solution is to increase a garment’s longevity through technology, rather than create low-quality garments containing poor quality fibre. Circular IDTM, Unmade and ByBorre offer examples of how to do this.

- Circular IDTM is a global standard and digital system that identifies products. Equipping a product with a digital identity allows for management in the circular economy.

- With the Unmade platform, consumers can see what they are going to buy before production. It is a software that will support individuality through production runs, rather than high minimum order quantities, whilst ensuring minimum use of resources.

- ByBorre boldly experiments with textiles through working with a circular knitting machine while minimising yarn wastage. Furthermore, their ground-breaking approach to production allows the garments to take on complex textures while maintaining minimalistic patterns and clean cuts.

With brands needing to design for longevity and encourage consumers to wear garments until production impact is neutralised, as part of our collaboration with SharpEnd for “Sustainable Stories” exhibition, we proposed a brand-consumer communicator where repair instructions could be obtained.

If you are interested in creating sustainable stories, making less but better through use of sustainably managed resources and sustainable production practices, do not hesitate to get in touch and let’s chat some more!

Posted 11 November, 2019 by Katie Kubrak