Sustainable Papers: Remake by Favini

At Nirvana CPH, we like to remind the brands we work with that sustainability cannot be designed backwards. Too often, projects are concepted, developed and designed, only for someone to cry, on the first day of production: ‘Wait! Is this sustainable?’

It doesn’t have to be this way. Asking big questions at the beginning of the design and development process – ‘What is the lifecycle of this thing I’m designing?’; ‘Does this project really reflect my brand’s commitment to environmental and social responsibility?’ – allows brands to make wiser, more responsible choices that build brand equity for the long term.

At the core of this decision-making process are materials – the tactile surfaces on which brands can begin to write their stories. Working in harmony with colours and finishes, materials have the power to deliver emotional connections with audiences in ways that excite, delight and inspire.

When it comes to paper, there are several criteria by which we can measure the broad concept of ‘sustainability’. A few weeks back, we highlighted some of the key things to look out for. From water consumption to carbon emissions, from recyclability to fibre source, there’s a lot of information out there; we’re here to cut through the noise and help you find the perfect fit for your brand.

At a time when brands (and their customers) are more conscious than ever about waste, paper manufacturers are working tirelessly to turn the unwanted and discarded into something of renewed value.

That’s why, this week, we’re shining the spotlight on an award-winning paper that repurposes offcuts from the leather industry, in an innovative example of how alternative fibres can be infused into the production process and, in turn, help brands to tell their own sustainable story.

REMAKE by Favini

The second on our list of “The Most Sustainable Papers for 2021” list is Remake, from Italian manufacturer Favini.

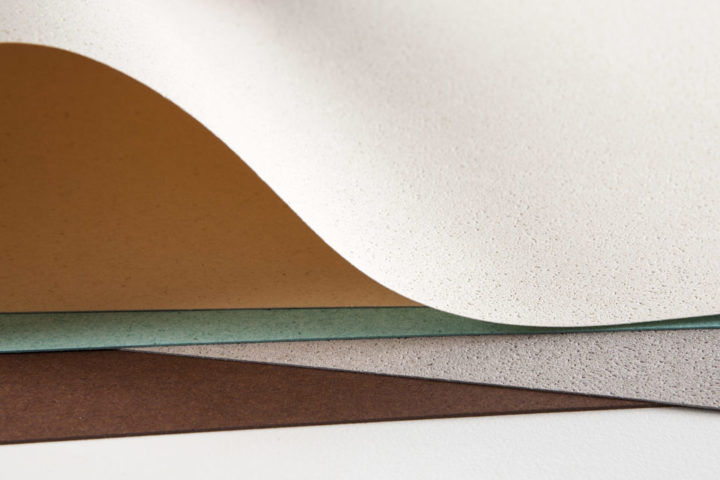

Remake is a high-end, eco-friendly, uncoated paper. However, its unique story lies in its alternative fibres, which constitute a proportion of the overall fibre mix.

It is made from the discarded residue of the leather manufacturing process and is a magnificent example of ‘upcycling’ in the paper sector. In this advancement, leather scraps are repurposed to create a new product of high quality and value.

Unsurprising, then, that this revolutionary process helped Favini secure a European Paper Recycling Award, back in 2017, in the Innovative Technologies and R&D category.

All of the scrap leather by-products used for Remake’s commercially available line are sourced from traceable Italian origin. The leather residues, which remain visible on the surface of the paper, give Remake its distinctive look and soft, velvety feel.

Certain premium brands, including Louis Vuitton, have partnered with Favini to create a customised version of Remake, using leather by-products from the brand’s own manufacturing sites. Not only does this give brands an outlet for their own waste material, but it also demonstrates a commitment to best environmental practice.

Speaking when Favini launched Remake in 2015, Eugenio Eger, the company’s CEO, said: “Genuine Leather industry waste is used to produce a regenerated leather or as fertilizer, and a portion is sent to landfill. Favini has developed a new process for the treatment of leather by-products in order to obtain a recyclable, biodegradable product that can be combined within traditional paper-production techniques. Thanks to REMAKE, we have increased our focus on industrial symbiosis processes and methods for reusing the by-products of other manufacturing segments (1).”

SUSTAINABILITY:

1. Source of fibre: 25% of alternative fibre source obtained from leather by-products, 40% of recycled PCW cellulose fibre, 35% FSC-certified virgin cellulose fibres.

2. Making process: Produced in Rossano Mill situated in Rossano Veneto, Italy. The hydrapulper at the Rossano Mill mixes various ingredients with water. These include virgin tree cellulose, post-consumer recycled fibre, fibres from annual plants (cotton, bamboo and bagasse), and pre-consumer by-products such as cutting trimmings or leather residues. The eventual characteristics of each making are subject to the proportion of different fibres in the mix. The production process is also Elemental Chlorine-Free (ECF), Acid Free, Carbon Black Free and Reach Compliant.

3. Energy: Remake is produced using EKOenergy. Favini owns two hydroelectric plants. 29% of self-produced hydroelectric energy was used to produce the upcycled papers including Remake paper line. Favini also holds a number of Energy Saving Certificates (ESC), which are a testament to their efforts of decreasing energy used.

4. Water: Water has multiple uses during paper production. It is used in the mixture, during coating and drying. For manufacturing, Favini uses water from bore wells, while it uses water from mains supply for personal uses (from the canteen to restrooms). A closed-loop water system has also been implemented in the paper mill: this allows for the reintegration of purified water from the plant, where possible. This recycling process has led to significant savings. Finally, wastewater is processed in an effective, eco-friendly purification plant that allows for the recovery of water that, given its high quality, interacts respectfully with the ecosystem of the water courses into which it is returned. Overall, between 2009 and 2018, the company was able to achieve a 40% reduction in water consumption.

5. Carbon emissions: Between 2009 and 2018, the company reduced its greenhouse gas emissions by 21%. To compensate for the unavoidable residual emissions from the Remake product line, the manufacturer undertakes specific environmental projects including The Akbük Wind Farm Project. This project involves the installation of 15 turbines and the development of a high voltage transmission line between the proposed project area and the national grid with the production of 105 GWh/year. The project’s contribution to sustainable development consists of a reduction of the greenhouse gas emissions; the creation of local employment, and; a contribution to the reduction of pollutants such as sulphur dioxide and nitrogen oxides.

6. Recyclability: At the end of life, Remake can be recycled and is biodegradable.

SUPPORTING INFORMATION

7. Functionality: Positioned to replace 100% virgin cellulose papers and through upcycling leather scraps. The leather residues equip the paper with a unique colour and feel.

8. Finishing: Remake is available in a smooth and carapace emboss surface finish. It is compatible with all method of printing, embossing, punching, die cutting, creasing, laminating and UV varnishing.

9. Weights: 120, 180, 250, 380, 520 gsm (available weights are subject to off-the-shelf colours)

10. Applications: Perfectly suited for a variety of applications, from brochures, shopping bags and swing tags, to menu covers, invitations and packaging – anything that a premium brand might require. In addition, some creatives have used Remake for artistic installations and decorative wall elements, making it an interesting material consideration for window displays, point-of-sale installations or pop-up shows.

11. Sustainable story: Remake reduces the amount of virgin fibres required to make high-quality paper, while introducing an alternative source of fibre through its unique partnership with the Italian leather industry. Its production aims to reduce the consumption of resources such as water and electricity while decreasing emissions of greenhouse gases. This paper can also be recycled and will therefore allow for the necessary resources to be reused as a new generation of paper products.

Notable brands that have used Remake to tell their story include Benetton Group (who chose Remake for all the swing tags of United Colors of Benetton), Vivienne Westwood (who partnered with Favini to produce exclusive packaging) and Louis Vuitton (who created a customised version of Remake Sand using their own leather by-products to produce an elegant suite of retail packaging).

A link to the manufacturer’s website can be found here and detailed description of the production process can be reviewed here.

If you like what you see, and require further information on any of the papers featured in our series, please contact info@nirvanacph.com. We’ll be more than happy to help you tell your brand’s sustainable story.

Posted 01 November, 2020 by Katie Kubrak