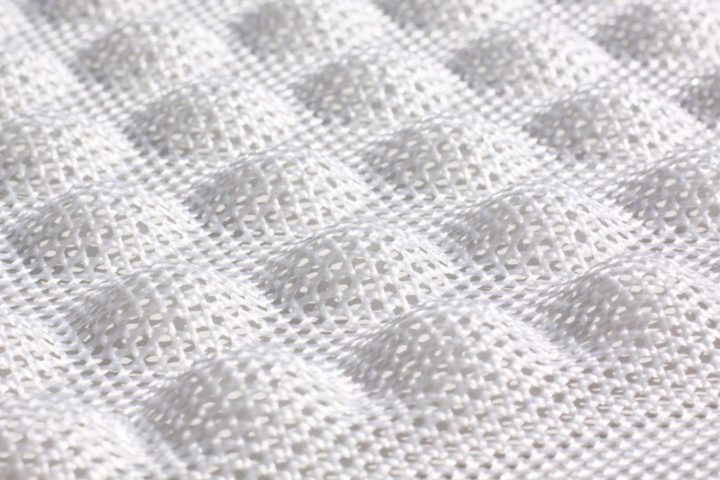

Triaxial Woven Fabric

It is increasingly common to see modern technology utilised to bring new applications to more conventional materials and applications. The multi-directional patterns featured in triaxial woven fabrics, which we discuss this Material Monday, are well aligned with a trend for a more engaging material experiences. Furthermore, surface of this material portrays vast opportunities for incorporating three-dimensional tactility into products and spaces that previously utilised two dimensional solutions.

Developed for the space program, triaxial woven fabrics are composed of three sets of yarns, which intersect and interlace with each other at 60-degree angles to impart uniform stability across the sheet. When woven with thermoplastic polyesters, the textile can be heat formed into a hollow 3-dimensional form that is both physically and visually lightweight.

Sublimely evocative patterns and depressions can be integrated into the surface with strategy of enhancing overall dimensional stability. Such approach can have a further positive impact on good resistance to strain and tears, improved surface strength, improved stability and durability compared to biaxial woven fabrics. Broad spectrum of weave patterns and densities is available to meet specific load requirements. What is more, the yarns that make up triaxial woven fabrics are available in a wide variety of colours and can be purchased in sheets or rolls format. Lastly, it is worth noting that these post an increased cost over other textiles due to the complexity of processing.

The weaving technique is commonly used within the medical industry and was used to produce stunning products like Issey Miyake’s bag and Ross Lovegrove’s ‘Seed of Love’ backpack. Acclaimed architects also used it in interior decorations and these include Minna no Mori at Gify Media Cosmos by Toyo Ito & Associates and Boutique Shang Xia in Shanghai by Kengo Kuma & Associates.

Triaxial woven fabrics offer both an interesting visual and tactile experience that can be integrated into products and spaces. Also, you can utilise these bespoke structural patterns, and almost translucent hollow exterior shell, to provide rigidity and impact resistance to packaging solutions. Other markets this surface could be used in includes, but is not limited to, consumer electronics, jewellery, automotive, furniture, sports equipment and interior accessories.

If you are interested to find out other exciting materials we have in our material library or you would like to book one of our London Design Festival 2018 workshops, please feel free to get in touch.

Posted 01 July, 2018 by Katie Kubrak