Sustainable Stories: How to use plastic responsibly? What’s the solution to the plastic problem?

Prior to 1950, reusable packaging had a nearly 96% return rate. By 1978, this had dropped to 5%, whilst the popularity of plastic rocketed. Very affordable production and competitive pricing of the material also influenced its low perceived value.

It was just over a decade later, when researchers noted recycling issues with plastic and also that 60-80% of ocean waste was non-biodegradable plastic, which is often washed up on land. In addition, figures indicate that 91% of all plastic is used just once and thrown away.

As a result, with the United Nations declaring “war” on single-use plastic, it’s hard to tell a sustainable story about plastic packaging. With low recycling rates, recycling issues, degradation of material integrity and single-use items ending up in landfill, plastic is modern society’s number one enemy.

And yet, despite its bad reputation, there are some positive uses of plastic in industries such as aviation, automotive and medical sectors, which is why education, disposal guidelines and transparency are key to sustainable design and positive consumer behaviour in the broader context of circular economy.

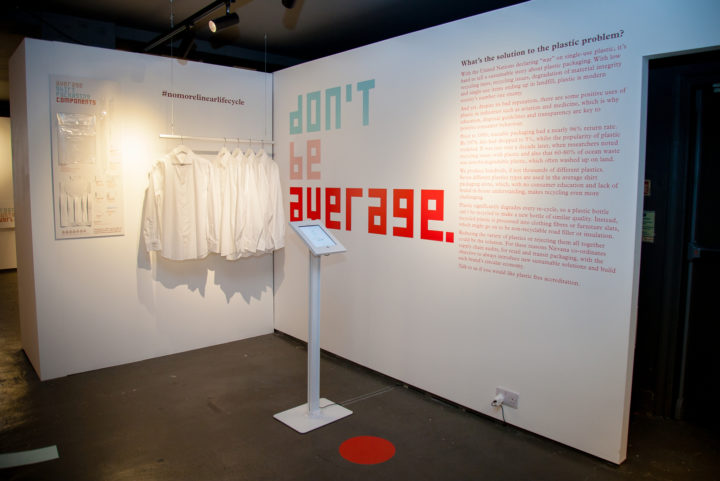

We produce hundreds, if not thousands of different plastics. Seven different plastic types are used in the average shirt packaging alone, which, with no consumer education and lack of brand in-house understanding, makes correct disposal and recycling even more challenging.

Plastic is a mixed loop material as it significantly degrades every time its recycled. This means that a plastic bottle can’t be recycled to make a new bottle of similar quality. As a side note, there is indeed a number of research projects by brands like Evian or Coca Cola to produce a bottle out of 100% recycled PET but at this point it’s uncertain to determine the environmental impact or resource consumption involved (e.g. water, energy). So at the moment, recycled plastic is processed into clothing fibres or furniture slats, which might go on to be non-recyclable road filler or insulation.

Reducing the variety of plastics or rejecting them all together could be the solution. For these reasons Nirvana co-ordinates supply chain audits, for retail and transit packaging, with the objective to always introduce new sustainable solutions and build each brand’s circular economy. We can also help you get a plastic-free accreditation.

To emphasise the need for material transparency, on the example of the aforementioned shirt packaging, we have presented a digital experience, in which a warehouse manager or consumer can scan an order and learn about all the different materials that went into making not only the garment but also the packaging. This was brought to life in collaboration with SharpEnd.

In the meantime, if you are interested in creating sustainable stories through transparent colours, materials and finishes, do not hesitate to get in touch and let’s chat some more!

Posted 15 December, 2019 by Katie Kubrak